Our Company Expands Production Capacity with the State-of-the-Art Trumpf TruLaser 3040 Bevel Cut

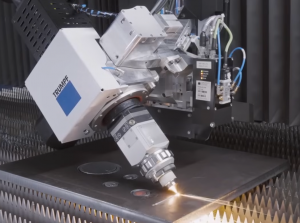

Our company has expanded its production capabilities with the latest laser cutting system – the Trumpf TruLaser 3040 Bevel Cut with bevel cutting technology.

This investment represents a strategic step towards greater efficiency, precision, and product quality. With the new machine, we are now able to offer an even broader range of services in metal cutting and processing.

What the New Laser Means for Our Custome

The TruLaser 3040 Bevel Cut is among the most advanced fiber laser systems available today. Equipped with the powerful TruFiber 12001 source, it enables fast, precise, and energy-efficient metal cutting, including bevel cutting (Bevel Cut) for weld edge preparation.

With this technology, our customers can expect:

Accurate cut parts with minimal tolerances

Weld edge preparation directly during cutting

Excellent cut quality without additional finishing

Shorter production times and faster delivery

Technical Specifications

Benefits of the New Technology

The new laser system brings not only higher performance but also significant technological advantages for production:

Maximum precision even in complex shapes and fine details

Time and cost savings thanks to clean, burr-free cuts

High flexibility in processing various materials

Consistent quality in both small-batch and serial production

Video Demonstration of This Technology

Ready for Your Projects

By investing in the Trumpf TruLaser 3040 Bevel Cut, we reaffirm our long-term commitment to innovation and quality.

The new equipment enables us to meet growing customer demands, shorten delivery times, and deliver precise components of the highest quality.

If you are looking for accurate laser-cut parts or bevel cutting services, contact our sales team — we will be happy to prepare a tailored quotation for your project.